Understanding Diesel Engine Manufacturers: A Comprehensive Guide

Introduction to Diesel Engine Manufacturing

The >diesel engine manufacturers play a crucial role in the global engineering and automotive industries. With the rise of environmentally friendly technologies and renewable energy sources, the diesel engine market has evolved significantly. This article will explore the critical aspects of diesel engines, the manufacturing process, and what you need to know when sourcing diesel engine parts and spare parts suppliers.

What is a Diesel Engine?

A diesel engine is a type of internal combustion engine that operates using diesel fuel. Diesel engines are widely recognized for their durability, efficiency, and power output. They power various applications, including heavy machinery, commercial vehicles, generators, and even marine vessels.

The Role of Diesel Engine Manufacturers

Diesel engine manufacturers are responsible for designing, engineering, and producing diesel engine systems. Their innovations have led to significant advancements in fuel efficiency, emissions control, and overall engine performance. Major manufacturers include companies like:

- Caterpillar

- Cummins

- MAN Energy Solutions

- Volvo Penta

- Detroit Diesel

These companies have established themselves as leaders in the diesel engine market, providing robust solutions to various industries.

Key Features of Diesel Engines

Understanding the features of diesel engines helps appreciate why they are widely used:

- Fuel Efficiency: Diesel engines are more fuel-efficient compared to their gasoline counterparts, which results in lower operational costs.

- Durability: Designed for heavy-duty applications, diesel engines often have a longer lifespan and require fewer repairs.

- Torque and Power: Diesel engines produce a significant amount of torque, making them ideal for heavy towing and hauling tasks.

- Lower CO2 Emissions: While diesel engines historically had a reputation for pollution, advancements in technology have led to cleaner emissions compared to older models.

Manufacturing Process of Diesel Engines

The manufacturing process of diesel engines encompasses several crucial stages:

- Design and Engineering: The first step involves designing the engine components, considering aspects like performance, efficiency, and emissions.

- Material Selection: High-quality materials are chosen for durability and strength, including engines made from iron and aluminum alloys.

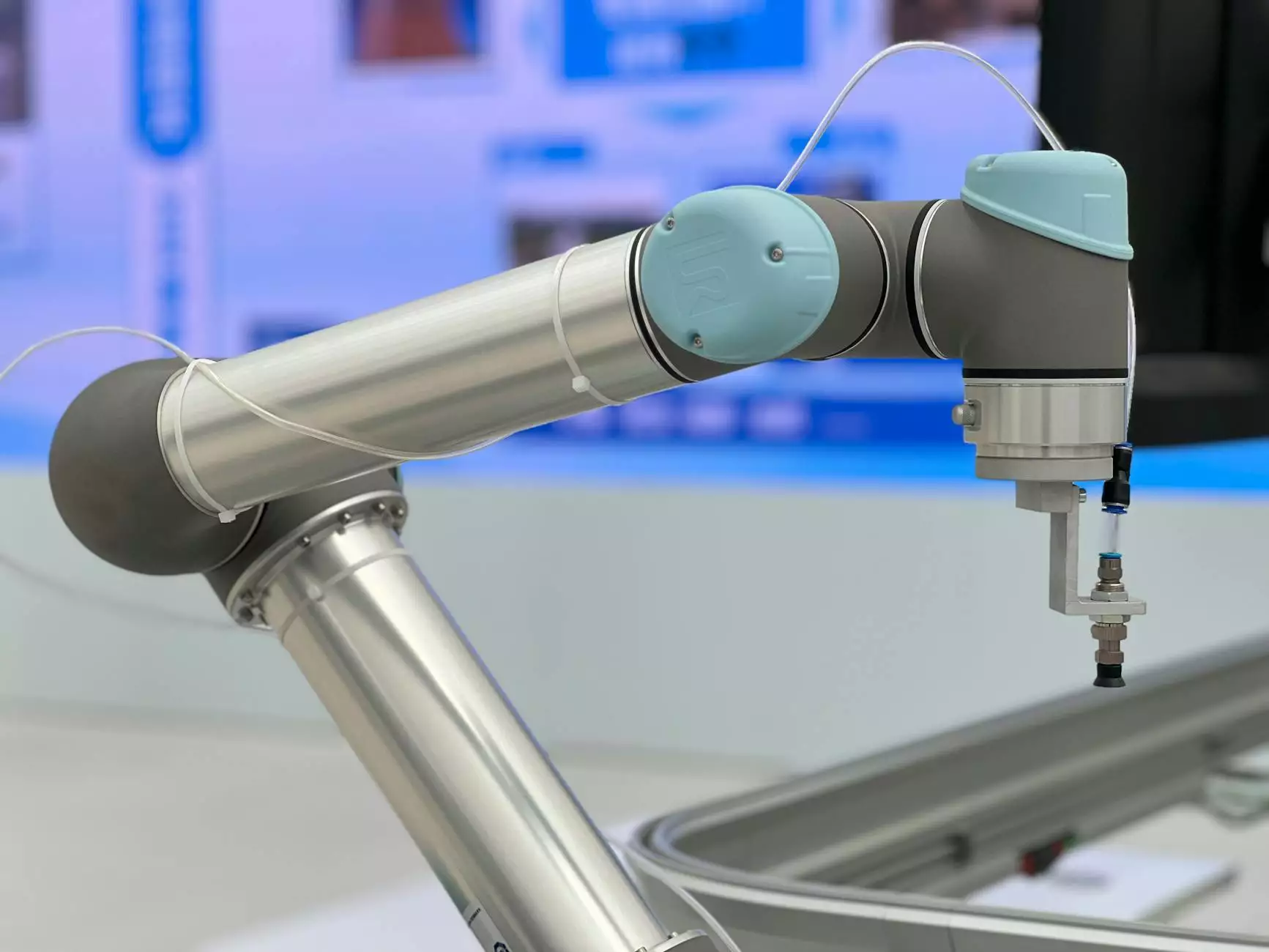

- Machining and Assembly: Modern technologies, such as CNC machining, are employed to create precise engine components, followed by assembly by skilled technicians.

- Testing and Quality Assurance: After assembly, each engine undergoes rigorous testing to ensure reliability and performance under various conditions.

- Distribution: Finally, the engines are distributed to OEMs (Original Equipment Manufacturers) or sold directly to consumers.

The Importance of Diesel Engine Parts

The longevity and performance of diesel engines largely depend on the quality of their parts. Key components include:

- Cylinders and Pistons: Essential for combustion and generating power.

- Fuel Injectors: Critical for ensuring precise fuel delivery for optimal performance.

- Turbochargers: Increase engine efficiency and power output.

- Crankshafts: Transfer power generated in the engine to the drivetrain.

How to Choose Reliable Spare Parts Suppliers

Choosing the right spare parts suppliers for diesel engines is paramount for maintaining high performance and reducing downtime. Here are some tips to consider:

- Reputation and Experience: Research suppliers' track records and industry experience.

- Quality Assurance: Ensure the supplier offers high-quality parts that meet or exceed OEM standards.

- Warranty and Return Policy: A reliable supplier will provide warranties on parts and a clear return policy.

- Customer Service: Good communication and customer support can make a significant difference in addressing any issues that arise.

Emerging Trends in Diesel Engine Manufacturing

The diesel engine industry is witnessing transformative changes due to technological advancements and environmental regulations:

- Hybrid and Electric Solutions: Many manufacturers are exploring hybrid technologies that combine diesel with electric drive systems.

- Emission Controls: Innovations in exhaust after-treatment systems are helping manufacturers meet stringent emission standards.

- Digitalization: Digital technologies like IoT (Internet of Things) are enhancing remote monitoring and predictive maintenance capabilities.

- Alternative Fuels: Research into biodiesel and synthetic fuels aims to reduce reliance on traditional fossil fuels.

Conclusion

In summary, diesel engine manufacturers form a backbone of industrial and automotive innovation. Their commitment to quality and efficiency continues to evolve in response to technological advancements and environmental challenges. By understanding the manufacturing processes, key components, and emerging trends, businesses can make informed decisions about purchasing diesel engines and sourcing the necessary parts. Partnering with reputable suppliers ensures reliability, performance, and sustainability in diesel engine applications.

Additional Resources

For further information, consider exploring the following resources:

- Client Diesel: Diesel Engine Parts

- Client Diesel: Spare Parts Suppliers

- Diesel Talk: Industry News and Insights